- Monday - Friday: 9.00am - 10.00pm

- rama.eng2004@gmail.com

Our Products

Rama Engineering Works is the Advanced Vibro Sifter Manufactures in Delhi. Our Vibro Sifter operates on a simple but effective system. The circular vibration generated by the vibrating motor pushes the material along the screen. As the material moves along, the smaller particles pass through the screen and the larger particles are directed to the discharge outlet. The process yields a uniform size distribution, improving the quality of the end product.

We are the Durable Vibro Sifter Suppliers in Delhi. Our Vibro Sifters possess a competitive advantage in the marketplace due to their precision engineering and reliability. Each unit is designed to sift bulk material with minimal loss of the end product. High-quality motors and precision-balanced components provide smooth running with minimal vibration. Our focus on user-friendliness means that our Vibro Sifters are easy to use, clean, and maintain. The simplicity of the design minimizes the risk of operational faults with maximum effectiveness. Our technical expertise also allows for tailored solutions to suit the specific requirements of your manufacturing process.

Consider us for all the needs of your Vibro Sifter in India. We prioritize strength, precision, and usability in all the Vibro Sifters that we manufacture. Our machines undergo strict quality checks to comply with the industry needs before they reach the customers. High-quality material and advanced manufacturing techniques ensure that our Vibro Sifters offer better performance even in the toughest conditions. From the initial contact to installation, maintenance, and technical support, we try to give your complete satisfaction. We understand the necessity of minimizing the downtime of industrial operations, and our service team is always ready to address your problems in a timely manner.

Rama Engineering Works is the Reliable Mass Mixer Manufactures in Delhi. The mass mixer is equipped with a specially designed mixing blade that ensures effective and uniform material mixing. The blade mixes the material in clockwise and anti-clockwise directions to give the material maximum contact. Hence, it is most appropriate for applications that demand uniform mixes without lumps. Our mass mixer is built with high-quality stainless steel to give strength, corrosion resistance, and industry hygiene compliance. The body of the machine is rigid to support heavy loads for hours without compromising the performance.

We are the Innovative Mass Mixer Suppliers in Delhi. The machine features a convenient tilting function for easy and spill-free discharge of the mixed material. The tilting system is operated manually or automatically, depending on the model, to prevent the risk of spillage and save the operator's time. The mass mixer is available in capacities of 5 kg to 500 kg (or more), depending on the need, to suit small- to large-scale production needs. The machine is also customizable to suit special needs, making it versatile for companies of various sizes.

Consider us for all the needs of your Mass Mixer in India. The machine is constructed with easy-to-access and simple components to enable easy maintenance and cleaning. The machine parts that come into contact with others can be sanitized within a short duration of time to avoid the risk of contamination as well as to comply with hygiene regulations, especially in pharmaceuticals and the manufacture of foods. Our mass mixers are constructed using SS304 or SS316 stainless steel that complies with Good Manufacturing Practice. This ensures that contact surfaces of the machine are safe to use with pharmaceuticals and foods. Apart from that, we have strict quality checks in the manufacturing process to ensure that our equipment is of international quality as outlined by the FDA and ISO.

Rama Engineering Works is the Robust Homogenizer Liquid Gel Manufactures in Delhi. Our homogenizer works by subjecting the material to high-pressure forces of shearing, impact, and turbulence. The gel or the liquid is pumped through a specially constructed valve or mechanical device that is tasked with disintegrating big particles into smaller ones. This guarantees that highly viscous fluids like gels or thick liquids, which would mix unevenly, have an even texture right to the microscopic level.

We are the Powerful Homogenizer Liquid Gel Suppliers in Delhi. The final result is a fully uniform product, like a skincare cream, a pharmaceutical syrup, or a food condiment. Apart from uniformity, the process of homogenizing also improves the final product's function and stability, which cannot be achieved by the use of common mixing equipment. The construction of a homogenizer needs quality material, like stainless steel, to offer strength, hygiene, and resistance to corrosion.

Consider us for all the needs of your Homogenizer Liquid Gel in India. During operation, the machine also operates with high pressure without a problem, even with highly viscous or thick products. Its heavy-duty build resists the wear and tear of long-term use, and therefore it is a long-term investment for industrial applications. For pharmaceuticals and the food processing industries, where safety and hygiene cannot be a compromise, the machine is manufactured to comply with strict regulatory requirements such as FDA regulations or ISO norms. The machine parts that touch the product are easy to clean and sterilize, with an added protection against the risk of contamination.

Rama Engineering Works is the Precise Planetary Mixer Manufactures in Delhi. Our planetary mixers have heavy-duty construction and advanced technology to mix a broad spectrum of material ranging from liquids and powders to highly viscosous mixtures like pastes, dough, or creams. The machine is particularly geared to applications that involve intricate mixtures of material such as emulsifying semi-solids or mixing solids into liquids. For example, in the pharmaceutical industry, it is used to mix suspensions, gels, and ointments to produce uniform distributions of the active ingredients. In the food industry, it is most suited to prepare whipped cream, batter, and sauces. Its versatility and dependability make it a great addition to production lines in different industries.

We are the Versatile Planetary Mixer Suppliers in Delhi. Our planetary mixer design also focuses on user convenience with simple-to-use controls that have a high level of accuracy. The operator is also capable of controlling the speed of the mix, the mix time, and the blade to achieve customized results for various processes. The machine also comes with a variety of replaceable mixing tools, such as paddles, scrapers, and whisk attachments, that the operator is capable of choosing depending on the application. A paddle, for instance, would mix thick pastes, while a whisk attachment would mix to aerate or whip lighter products like mousses or creams. Such versatility makes the machine highly versatile to various production needs.

Consider us for all the needs of your Planetary Mixer in India. The planetary mixer also features optional vacuum or heating systems to meet special mixing requirements. For temperature-controlled operations, such as the production of chocolate or emulsions, the heating jacket enables the product to reach the best conditions without the need for human intervention. The vacuum function also accommodates degassing of air in thickened products, such as adhesives or gels, to create a smooth, blemish-free end product. These features to customize the mixer make the planetary mixer an indispensable and highly versatile machine for businesses with special or demanding mixing operations.

Rama Engineering Works is the Automated Cream Manufacturing Plant Manufactures in Delhi. The system is an interconnected network of primary parts that comprise the main mixing vessel, wax phase vessel, water phase vessel, homogenizer, transfer pumps, and filtration systems. The double-jacketed primary mixing vessel is designed to heat, cool, or vacuum to maintain precise temperature control of the emulsification or cream-making process. The water and wax phase vessels combine the ingredients with precision to produce the desired consistency of the raw material before addition to the primary vessel. A high-speed inline homogenizer is included to mix and disintegrate particles, create stable emulsions, and increase the texture and finish of the final product. Transfer pumps provide smooth material transfer between the vessels, automate the process, and eliminate the need for human intervention.

We are the Streamlined Cream Manufacturing Plant Suppliers in Delhi. Our factory is constructed to achieve maximum production efficiency by combining automated controls, reduced energy consumption, and optimized mixing technology. The vacuum system degasses the cream to remove air bubbles, giving a smooth final product that is bubble-free and uniform. The system accepts multiple ingredients of varying viscosities, mixing them into an emulsion. Its high-performance mixing blades and inline homogenizer provide uniform distribution of active ingredients, preservatives, and stabilizers, making it ideal for pharmaceutical and cosmetic applications that cannot afford inconsistency. The process is scalable and customizable, allowing manufacturers to produce different needs without sacrificing quality.

Consider us for all the needs of your Cream Manufacturing Plant in India. All the contact parts of the cream manufacturing unit are made of food-grade or pharmaceutical-grade SS316/SS304 stainless steel to offer high hygiene and compliance with industry standards like GMP, FDA, and ISO. The system is simple to clean, with CIP (Clean-In-Place) or SIP (Sterilization-In-Place) provided to minimize downtime and contamination risk. The sealed design prevents environmental impurities, and the final product remains of quality and safety standard. The plant is especially suited for the production of sensitive pharmaceutical and personal care products.

Rama Engineering Works is the Customizable Syrup Manufacturing Plant Manufactures in Delhi. Our syrup manufacturing factory is built with the latest technology to suit various capacities of production, giving the user a highly reliable and automated system that eliminates human error, improves productivity, and maintains strict hygiene. Our factory is designed to meet your operational needs by ensuring accurate preparation, mixing, and filtration of all the ingredients with strict quality and safety checks along the way.

We are the High-performance Syrup Manufacturing Plant Suppliers in Delhi. The factory consists of large-scale integrated equipment, all of which have been designed to enhance efficiency and versatility. These include a melting vessel for the sugar, a pre-filtration vessel, a syrup-making vessel, an inline homogenizer, storage tanks, and transfer pump systems, as well as temperature and agitation automation controls. The melting vessel for the sugar effectively dissolves the sugar in water, and the syrup-making vessel allows precise control for the mixing of active ingredients, stabilizers, colors, and flavors. The vessel is generally equipped with a heating and cooling jacket to give an optimal process condition.

Consider us for all the needs of your Syrup Manufacturing Plant in India. Our syrup-making factory is designed to optimize every step of the process with minimal waste and low operational cost. The fully automated features simplify the production processes with precise controls over temperature, mixing times, and agitation rates. High-level control panels offer an easy-to-operate interface, allowing the operator to monitor the production processes in real-time and make the necessary adjustments without having to stop the process. Automation ensures repeatability and accuracy of the recipes, with the quality of each batch being the same.

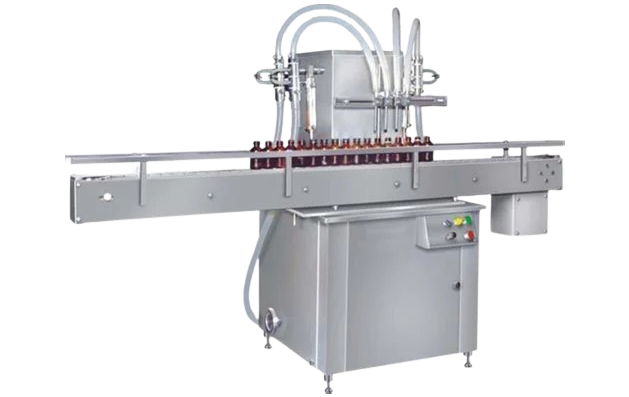

Fully Automatic Liquid Filling Machine

Rama Engineering Works is the effective Fully Automatic Liquid Filling Machine Manufactures in Delhi. Our filling machine is designed to eliminate the inaccuracies and inefficiencies of manual and semi-automatic filling processes. With a completely automated process that handles everything from filling with liquids and bottle position to closing and applying the caps, depending on the application, the full automation eliminates human error, increases productivity, and gives uniform results, making it an indispensable addition to any factory.

We are the reliable Fully Automatic Liquid Filling Machine Suppliers in Delhi. The fully automatic filling machine uses state-of-the-art technology to achieve high-speed, error-free operations. The PLC system allows the filling cycles to be pre-programmed to make operations easy and ensure batch-to-batch consistency. Fill volume, production speed, and automatic cut-off parameters can be input by the operator via an intuitive touch screen, giving full control of the production process. The machine also comes equipped with sensors to detect faults like out-of-alignment bottles, low level of the liquid, or blockage of the nozzles with minimal down-time.

Consider us for all the needs of your Fully Automatic Liquid Filling Machine in India. If your business needs a reliable, accurate, and high-capacity filling system for liquids, our Fully Automatic Liquid Filling Machine is the ideal choice. Efficient, customizable, and versatile to a wide range of liquids and packaging, it allows easy integration into your production line with reliable results. Engineered with hygiene in mind, built with precision, and optimized for productivity, the machine guarantees quality and smooth operations, making it easy to achieve your production goals.

Fully Automatic Paste Filling Machine

Rama Engineering Works is the major Fully Automatic Paste Filling Machine Manufactures in Delhi. Our highly advanced paste filling machine features sophisticated control systems to achieve high-speed operation, reproducible accuracy, and the versatility to fill different container sizes and paste compositions. From thick foods such as peanut butter or ketchup to industrial adhesives and cosmetic creams, the machine is the best solution for manufacturers that demand consistency and effectiveness in paste-filling operations. Due to its long-lasting construction and adherence to safety and hygiene norms, it is the best suited to meet the stringent demands of high-capacity production plants.

We are the Sophisticated Fully Automatic Paste Filling Machine Suppliers in Delhi. The most salient feature of our fully automatic paste filling machine is its piston-based filling system that ensures accurate dosing of the paste products. The piston system is effective in handling thick pastes without any difficulty, smoothly sucking the paste and discharging it into the containers without any air pockets or unevenness. The machine is adaptable and accommodates a variety of container shapes and sizes, including jars, tubs, bottles, and pouches, making it highly versatile in packaging options.

Consider us for all the needs of your Fully Automatic Paste Filling Machine in India. Our fully automatic paste filling machine is used extensively across different industries to manage a broad variety of paste products. In the pharmaceutical industry, it fills gels, ointments, lotions, and creams into tube, jar, or other containers with precise dosage. The food and beverage industry relies on it to fill ketchup, mayonnaise, peanut butter, and jams with uniform fill levels and a sanitary process.

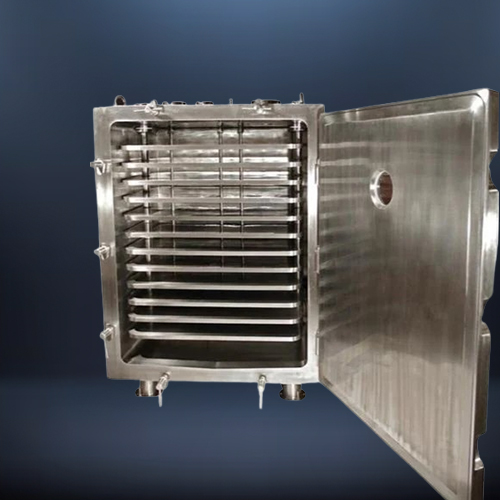

Rama Engineering Works is the Resilient Tray Dryer Manufactures in Delhi. The tray dryer operates on the principle of convection, with hot air being blown over the material loaded on trays inside a highly insulating drying chamber. Controlled temperature and airflow give the maximum heat transfer, ensuring effective and uniform evaporation of moisture without over-drying or compromising the quality of the product. Our tray dryers possess the special advantage of having an even temperature across all the trays to give batch uniformity. Being multi-tray capable, it effectively tackles mass-scale drying requirements without sacrificing energy consumption.

We are the Scalable Tray Dryer Suppliers in Delhi. Our tray dryer is performance-oriented, long-lasting, and hygienic. The dryers have SS304 or SS316 stainless steel construction to offer better corrosion resistance, long-term life, and compliance with stringent industry norms like GMP and FDA. The double-walled thermal-insulation of the drying chamber prevents heat loss to the system, thus making the system energy-efficient and reducing the cost of operations. High-temperature gaskets ensure tight sealing to preserve controlled airflow and prevent leakage of heat.

Consider us for all the needs of your Tray Dryer in India. Our tray dryer's cutting-edge drying technology guarantees uniform heat distribution throughout the chamber with its high-velocity fans and carefully designed air ducts. The thermally insulated body retains the heat effectively, with forced hot air distributed evenly across all the trays to dry out the material without weakening the structural integrity of the product. Depending on the material, the dryer introduces an optimal level of heat and airflow to prevent degradation, clumping of the product, or texture loss.

Rama Engineering Works is the major Mixer Vessel Manufactures in Delhi. The mixer vessel is equipped with the most advanced mixing technology that offers ensured uniform mixing, effective agitation, and complete homogenizing of the ingredients. The heart of the vessel is its agitator system, which is designed to suit specific process requirements. Agitator options include anchor-type agitators, paddle agitators, propeller mixers, and turbine mixers, all of which are designed to process different formulas of thin liquids to thick, high-viscosity pastes. The mixer shaft and the blades are designed to withstand hard and long-term operations and have the capability of running for hours without failing.

We are the reliable Mixer Vessel Suppliers in Delhi. Our mixer tanks also have sophisticated automation with Programmable Logic Controllers (PLCs) to offer simplicity of operation, accuracy, and reproducibility of the process. The process parameters of temperature, speed, and mixing duration are managed by easy-to-operate touch-screen displays. A number of pre-programmed programs offer batch production with uniformity and avoid the risk of human error.

Consider us for all the needs of your Mixer Vessel in India. Sensors and feedback systems are merged to monitor the process in real-time and achieve effective operations with minimal material loss and maximum productivity. Alarms for any deviation like temperature deviation or overloading are also available for safety. Data logging and remote monitoring are also possible with the automation system, providing full visibility to the mixing process and traceability for batch production, a key requirement for pharmaceutical and food manufacturers. For applications requiring sterility, vessels can also be designed to operate in cleanrooms or aseptic environments and with HEPA-filtered air supply systems. With the customization of the vessel to your exact specifications, we offer the most effective and reliable solution to your business.

Request A Quote

-

01

What industries do you serve?We manufacture high-quality machinery for the pharmaceutical, cosmetic, and food industries, helping businesses streamline their production processes with advanced automation and precision engineering. -

02

Do you provide customized machinery?Yes! We offer customized solutions based on your specific production requirements. Our team works closely with clients to design and manufacture machinery tailored to their needs. -

03

What types of machines do you offer?Our product range includes:- Vibro Sifter

- Mass Mixer

- Homogenizer Liquid Gel

- Planetary Mixer

- Cream Manufacturing Plant

- Syrup Manufacturing Plant

- Fully Automatic Liquid Filling Machine

- Fully Automatic Paste Filling Machine

- Tray Dryer

- Mixer Vessel

-

04

Do you provide after-sales service and spare parts?Yes, we offer comprehensive after-sales support, including maintenance services, technical assistance, and genuine spare parts for all our machinery.